Polyurethane Foam

Polyurethane (PU) foam is everywhere in modern life. There are two main types:

- Flexible PU foam: Light, durable, soft, and comfortable. Used in mattresses, upholstered furniture, automotive interiors (car seats, dashboards), carpet underlays, etc.

- Rigid PU foam: Dense, strong, and excellent for insulation. Often used in building walls, roofing, and anywhere thermal insulation or noise reduction is needed.

Because PU foam is so widely used, there's a lot of waste generated — off-cuts, production scrap, end-of-life items.

Reasons FOR Polyurethane Foam Waste Recycling

- PU foam is non-degradable and considered plastic; if unmanaged, it contributes to environmental pollution and “white pollution.”

- Recycling helps reduce landfill use, lower environmental impact, conserve resources.

- There are two main recycling approaches:

- Mechanical recycling: Reuse or re-bond the polymer foam physically (e.g. re-bonded foam underlayment, cushioning).

- Chemical recycling: Break the foam back into its chemical constituents for reuse as raw materials.

Importance of a Polyurethane Foam Baler

Because of its nature, PU foam has very low density, which brings challenges:

- Bulky, voluminous material takes up space.

- Transporting or storing loose foam is inefficient and expensive.

A foam baler helps by compacting foam into dense, regular-shaped bales. This leads to:

- Lower volume → saves on storage space.

- Easier, safer handling and stacking of the material.

- Reduced transportation costs. Regular shaped, denser bales cost less to move.

- More efficient downstream recycling / processing since the foam is already in a manageable form.

Applications of Polyurethane Foam Balers

Polyurethane foam balers are utilized across various industries to manage foam waste effectively:

- Foam Manufacturing: Compressing production scraps into bales for easier handling and recycling.

- Automotive Industry: Managing foam waste from vehicle interiors and components.

- Furniture Production: Handling off-cuts from mattresses and upholstered furniture manufacturing.

- Recycling Facilities: Processing foam waste for further recycling or disposal.

- Packaging Industry: Compressing foam packaging materials for recycling.

Contact SINOBALER today to define your foam type, bale size, density needs, and recommend the right baler to suit those needs.

Quick links:

VIDEOS

PICTURES

APPLICABLE MACHINE

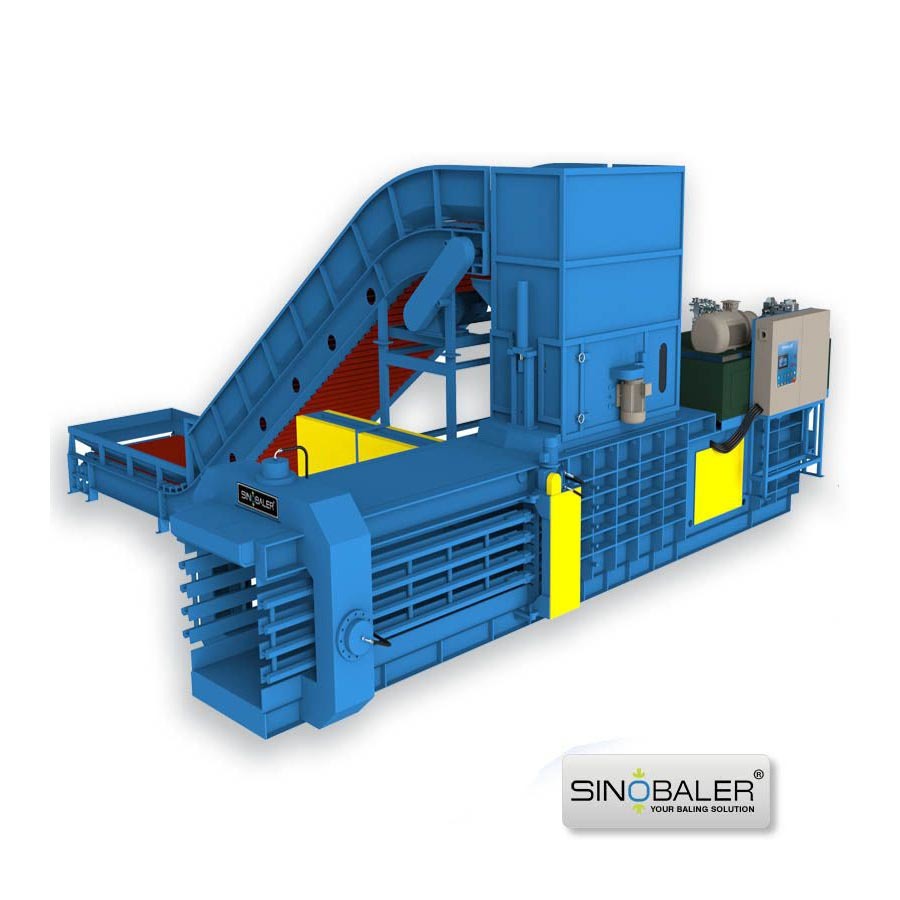

Foam Shredding & Compacting Plant

This integrated foam shredding and compacting plant processes EPS and XPS foam via a mechanical, pollution-free cold pressing system. It includes an infeed conveyor, foam shredder, blower, silo, auger feeder, and hydraulic compactor—no foam densifier required—allowing safe operation even in residential areas. The system produces flat, dense blocks (over 360 kg/m³) with a 40:1 compression ratio, maximizing transport efficiency. Two compactor models are available to meet various productivity needs.

The Sinobaler Heavy Duty Dual Ram Baler delivers 80–200 tons of press force via its dual-ram system, ideal for compacting tough, fibrous, or rebounding materials, as well as soft ones requiring high bale density for optimized loading. It's perfect for natural and synthetic fibers, metal panels, tubes, profiles, and hard plastics like electronics shells and pipes. This baler reduces storage space, cuts transport costs, and boosts efficiency—making it a smart investment for modern recycling and waste handling.

Sinobaler’s Manual Tie Horizontal Baler, also called a semi-automatic horizontal baler, handles solid and hollow waste like cardboard, PET bottles, textiles, and more. Ideal for facilities processing under 4 tons/hour with low labor costs, it offers automatic feeding, compressing, door control, and bale ejection—only the tying is manual. Press force ranges from 40 to 120 tons, with bale weights from 200kg to 850kg. Custom chamber sizes, power packs (up to 45kW), and conveyor options are available to boost productivity up to 5 bales/hour.

Open-end Manual-tie Horizontal Baler

Sinobaler SHB1-O series open-end manual-tie horizontal baler features an open-end design for continuous bale output, improving productivity by 50% over close-end balers. Strapping setup is needed only once, saving labor like a fully automatic baler. It supports various strapping materials—steel wire, PET strap, rope, etc.—making it ideal for high-volume solid waste or biomass baling. Not suited for hollow plastics due to lower density. A cost-effective choice for mid-scale recyclers or facilities needing efficient, labor-saving baling with limited investment.

Open-end Manual-tie Horizontal Baler With Wire Threader

This open-end manual-tie horizontal baler with wire threader offers nearly all functions of a fully automatic baler—except automatic tying. The built-in threading mechanism pushes wire or belt into strapping slots automatically, unlike standard manual-tie balers. While its productivity is about 20% less than a full-auto baler of the same size, it allows flexible strapping materials like steel wire, PET belt, or rope. Ideal for medium-scale recyclers or producers of solid waste, animal bedding, or feed who need efficient, cost-effective baling without sharp metal in bales. Best suited for soft or solid waste, not hollow plastic containers.

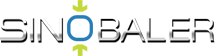

Fully Automatic Horizontal Baler

Sinobaler’s fully automatic horizontal baler (20–120 tons pressure) processes up to 15 tons/hour, ideal for high-volume recyclers handling cardboard/OCC, paper, plastic film, textile waste, and more. As our flagship open-end auto-tie baler, it features Mitsubishi PLC control, remote support, and simple operation. Bale weight/length is programmable via a touch screen for optimized container loading. The SHBA2-1200 model produces dense 1200kg rectangular bales, easy for transport/storage. CE-compliant with safety interlocking, SHBA2 is the perfect solution for large-scale soft waste recycling.

L-type Two Ram Automatic Horizontal Baler

The L-type two ram automatic horizontal baler is ideal for baling a wide range of recyclable waste. Compared to single ram balers, it offers greater versatility, supports both wire and plastic strapping, and produces high-density bales thanks to its separate strapping unit. Its flexible design can include features like a pre-compression lid to prevent cutting sensitive materials like textiles. Perfect for high-volume recycling centers, fodder exporters needing plastic straps, and municipal waste handlers seeking to avoid jams common in single ram balers.

Cardboard Baler (eg. Mill Size Baler)

The standard mill size baler is one of Sinobaler’s most popular vertical baling machines, ideal for handling cardboard and carton waste. Also known as a cardboard or carton baler, it suits recycling centers, cardboard manufacturers, supermarkets, stores, and print shops generating large cardboard waste. It compresses waste into dense bales up to 520kg with a size of 1520×760×1220mm, reducing volume by about 12:1. Easy to operate with manual door opening and auto bale ejection, it saves storage space, transport, and labor costs while meeting safety standards.

Mini Baler / Marine Baler / Multi Purpose Baling Machine

Sinobaler’s Multi-purpose Baler (Mini Baler) is a compact, versatile vertical baler ideal for malls, hotels, offices, hospitals, houses, and vessels, making it popular as a Marine Baler due to its small footprint and height. It meets marine industry needs with standard, waterproof, and explosion-proof versions, helping over 300 vessels reduce waste storage and disposal costs by up to 60%. This baler handles soft waste like cardboard, paper, cans, bottles, and film, with 10–20 tons press force, up to 800×600×800mm bale size, 20–100kg bale weight, and 12:1 compaction ratio for easy storage and transport.

PRIVACY POLICY

We collect information from you when you fill out an inquiry or contact form. When submitting the form on our site, you may be asked to enter your name and contact details such as: e-mail address, mailing address and/or phone number, etc. Alternatively, you can choose not to complete our forms and visit our site anonymously. Any of the information we collect from you may be used to help us to better respond to your individual needs, and/or enable us to more effectively respond to your customer service requests and support needs. The email address you provided may also be used to send you information and updates pertaining to your inquiry and/or order, in addition to receiving occasional company news, updates, related product or service information, etc. SINOBALER does not sell, trade, or otherwise transfer to outside parties your personally identifiable information. This does not include trusted third parties who assist us in operating our website, conducting our business, or servicing you, so long as those parties agree to keep this information confidential. We may also release your information when we believe release is appropriate to comply with the law, enforce our site policies, or protect ours or others rights, property, or safety.

By using our site, you consent to our online privacy policy. If we decide to change our privacy policy, we will post those changes on this page. If you have any questions or concerns regarding our privacy policy, please e-mail info@sinobaler.com or mail your question to us at 1206 Yinzhou Shanghui Nan Lou, 1299 Yinxian Avenue, Yinzhou District, Ningbo 315192, P.R. China.

EXTERNAL LINKS & DISCLAIMER

Our web site has links to many other organizations with their permission. Upon leaving the SINOBALER web site, you are subject to the privacy policy of the new site which are not under our control. SINOBALER is not responsible for the content of any linked site or any link contained in a linked site. These links are provided to you as a service for you to better understand the different business relationships that SINOBALER has established, and/or to point the reader to other possible relevant resources.