Biomass Bagging Baler

A biomass bagging baler is an efficient and practical solution for packaging loose biomass materials. By compressing and sealing biomass into bags, it improves storage efficiency, simplifies transportation, and protects material quality. For biomass recycling, energy production, or export applications, biomass bagging balers deliver reliable performance and excellent economic value.

Product description

SINOBALER Biomass Bagging Baler is an efficient solution for reducing the volume of loose biomass while improving handling, storage, and transportation efficiency. It compresses loose biomass material into high-density bales and pack them in protective bags, effectively shielding materials from moisture and dust.

Designed to process a wide range of biomass materials—such as hay (alfalfa, grass), straw, wood shavings, sawdust, corn silage, bagasse, plant stalks, and other agricultural or forestry residues—the machine delivers uniform, compact bales with significantly reduced logistics costs.

Widely used in biomass fuel production, animal feed and bedding, growing media, composting, renewable energy plants, and agricultural supply chains, this Biomass Bagging Baler helps maximize material value while ensuring clean, efficient, and cost-effective biomass management.

Key Benefits of Biomass Bagging Balers

- Significant Volume Reduction

Loose biomass is compressed into dense, bagged bales, dramatically reducing storage space and lowering transportation costs. - Clean and Well-Protected Packaging

The bagging function protects biomass from moisture, dust, and external contamination, helping maintain consistent material quality. - Easier Handling & Faster Logistics

Bagged bales are stable and easy to stack, move, and load, improving efficiency in warehouses, containers, and truck transportation. - Wide Material Compatibility

Designed to handle a broad range of biomass materials—including light, fluffy, and irregular forms—making it suitable for diverse applications.

Choose from our various models available, or contact us for a customized baling solution.

Main Features

- Twin-Chamber Structure

Delivers higher compression efficiency, ensuring dense, uniform, and well-shaped bales. - PLC Control System

Fully automated operation with precise control, improving consistency, accuracy, and operational reliability. - One-Button Operation

Simplified control allows continuous compressing and automatic bale ejection for high productivity. - Integrated Cutting Blades at Feed Aperture

Effectively cuts long or fibrous materials, preventing bridging or jamming during ram movement. - Bagging Chute System

Enables packing of finished bales into sleeve bags or closed bags, protecting materials from environmental exposure while maintaining bale integrity. - Optional Feed Conveyor

Supports continuous and automatic material feeding, significantly reducing labor requirements and improving overall efficiency.

Specifications

| Model | Bale size | Bale weight (for alfalfa) | Throughput | Strapping | ||

|---|---|---|---|---|---|---|

| Length | Width | Height | ||||

| SHB1-WS-1200 |

1120 mm (44 inch) |

1180 mm (46 inch) |

850 mm (33 inch) |

340-360 kg (748-814 lbs) |

20-25 bales/hr |

Plastic bag, woven bag, etc. |

| SHB1-WS-1600 |

1120 mm (44 inch) |

1180 mm (46 inch) |

850 mm (33 inch) |

380-420 kg (836-924 lbs) |

21-27 bales/hr |

|

| SHB1-WS-2000 |

1120 mm (44 inch) |

1180 mm (46 inch) |

850 mm (33 inch) |

430-480 kg (946-1056 lbs) |

22-28 bales/hr |

|

RELATED VIDEO

BALING Applications

Hay (e.g. alfalfa, grass), straw, wood chips/shavings, sawdust, rice husks, corn silage/stalks, bagasse, sugarcane stalks, etc..

RELATED Baler Accessories

FAQ about this machine

Feeding materials into a baler can be done in various ways depending on the type of materials, the equipment involved, and the setup of the baling system. Here’s a breakdown of some common feeding methods:

1.Excavator:

- Used for: Large, bulkier materials like scrap metal, wood, or other heavy materials.

- How it works: An excavator with a bucket or grapple is used to load materials into the hopper or feed opening of the baler. The excavator can precisely place materials into the feeding area.

- Advantages: Ideal for large-scale operations, especially when materials are heavy or difficult to move manually.

2. Air Cyclone:

- Used for: Light, fluffy materials like paper, plastic, or other recyclables that need to be separated from dust and debris.

- How it works: An air cyclone system uses airflow to move lightweight materials into the baler. It can also help in separating light materials from heavy ones before they enter the baling chamber.

- Advantages: Great for automating the process and improving efficiency when dealing with fine materials or mixed waste.

- Used for: Continuous feeding of materials like cardboard, plastics, textiles, or paper.

- How it works: Materials are loaded onto a conveyor belt, which moves the materials to the baler’s feed hopper. The conveyor can be configured to run automatically or manually, depending on the material flow and system design.

- Advantages: Ideal for continuous, high-volume feeding, especially in automated recycling plants or warehouses.

4. Dumper (Tippers):

- Used for: Materials in bins or containers, such as industrial waste, textiles, or recyclables.

- How it works: A dumper or tipper lifts a container of materials and dumps it directly into the baler’s feed hopper. This is often seen with bulk bins or compacted waste.

- Advantages: Simple and effective for large quantities of materials that are pre-loaded into containers. It reduces manual labor and speeds up the feeding process.

5. Other options:

- Manual Feeding: For smaller-scale operations or when dealing with materials that require sorting, workers might feed materials directly into the baler using forklifts or by hand.

- Forklift: Can be used to lift and drop larger bales or materials into the baler’s feed area.

Each of these methods can be adapted based on the specific baling process, material type, and operational needs. For maximum efficiency, it's important to match the feeding method to the material characteristics and volume.

Upon releasing your baling machine from our factory, we will indicate the required amount of hydraulic oil based on your working condition and environment temperature, and reflect it as Best Oil Level for your baler.

You can easily refer to the “Best Oil Level” stickers as a gauge when you are filling up the oil tank and conduct regular checks on oil level (as seen on picture, slight variation above or below the level line is acceptable).

Taking into consideration that actual operation hours and conditions may varies from time to time, regular checks on oil temperature and level is strongly recommended.

Best Oil Level sticker

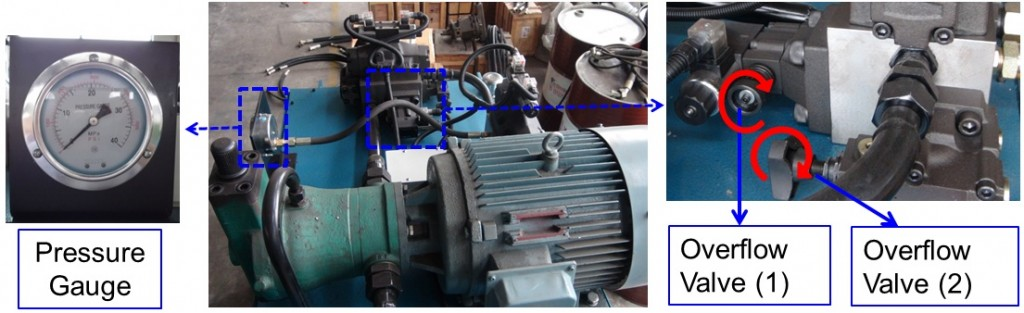

Increasing or decreasing the compressing pressure will directly affect the density of your bale. Please follow the steps below to learn how to adjust compressing pressure on your baling machine. We strongly advise you to refer to the safety working pressure stated on your Operator Instruction Manual to ensure you don’t go above the limit.

Pressure adjustment steps for Heavy Duty Horizontal Bagging Baler:

1. Turn on the power and start the motor.

2. Adjust overflow valve (2) by turning the plastic knob clockwise (as per the red arrow) during baling. Observe the pressure gauge at the same time to monitor the increase of pressure. For your info, turning the knob anti-clockwise will decrease the pressure.

3. However, if the pressure did not go up after adjusting overflow valve (2), please go to overflow valve (1) and turn the knob clockwise as per the red arrow. Observe the pressure gauge at the same time to monitor the increase of pressure.

NOTE:

– Adjust the valve slowly to achieve higher pressure, check the pressure gauge at all time so as to not increase too much at one time.

– The recommended pressure has already been set at our factory before delivery. Therefore, do not make any adjustment to pressure unless it is necessary.

Hydraulic Oil should be changed after the first 6 months of operation (or after 1500hours of operation), and thereafter changed once a year (or after 3000 hours of operation). The following steps teaches you to drain oil in cylinders away to ensure you can replace with new oil completely.

For Main Cylinder:

Hose 1 (bigger) – Oil inlet (Ram forward)

Hose 2 (smaller) – Oil outlet (Ram backward)

Instructions:

1. Dismantle both hose 1 & 2 at valve block.

2. Place “hose 2” into the used oil receiving container, then connect “hose 1” to your compressed air system.

3. The compressed air system will push piston to move forward and oil will be released through hose 2.

4. Once oil is drained, connect your compressed air system to “hose 2” to reset piston back to original position.

For Ejecting Cylinder:

Hose 1 – Oil inlet. (Ejector forward)

Hose 2 – Oil outlet. (Ejector backward)

1.Dismantle the hose joints for both hose 1 & 2.

2.Dismantle the “Trigger Ring”.

3.Place “hose 2” into the used oil receiving container, then connect “hose 1” to your compressed air system. The compressed air system will push piston to move forward and oil will be released through hose 2.

4.Once oil is drained, connect your compressed air system to “hose 2” to reset piston back to original position.

5.Assemble the “Trigger Ring” back to original position.

Ejecting a bale from a baler depends on the type of baler (vertical or horizontal) and the material being baled. Here’s a detailed guide:

Safety First

- Ensure the baling cycle is fully complete and the compression ram is fully retracted.

- Clear the area around the ejection path.

- Use appropriate PPE (gloves, shoes, safety goggles).

The Type of Balers

- Common for: Small to medium bales, light materials like cardboard, textiles, aluminum, or plastic.

- Steps to Eject:

- Ensure the baling cycle is complete and the ram is fully retracted.

- Open the front door or chamber door.

- The compressed bale usually drops onto the built-in floor or rollers. You may need to push it slightly with a lever or tool.

- Remove the bale manually or with a pallet jack/forklift if needed.

- Close the door and reset the baler for the next cycle.

- Ensure the baling cycle is complete and the ram is fully retracted.

- Common for: Larger bales, heavier materials like metals, plastics, hay or textiles.

- Steps to Eject:

- Complete the baling and tying cycle.

- Activate the bale ejection system (often hydraulic). This pushes the bale out of the compression chamber. For fully automatic balers, the system automatically ejects the bale onto a conveyor or into a receiving area after compressing and tying.

- The bale is pushed onto the bale chute, conveyor, or floor, depending on the model. For fully automatic balers, operators only need to ensure the path is clear for the bale.

- Use a forklift, pallet jack, or grabber to move the bale to storage or shipment.

- Complete the baling and tying cycle.

Manual or the Available Equipment

1. Manual Handling (Small Bales)

- Suitable for lightweight bales.

- Steps:

- Ensure the baler has completed the compression and tying process.

- Open the ejection door carefully.

- Slide the bale out onto a pallet or a flat, stable surface.

- Use proper lifting techniques to avoid injury (bend knees, keep back straight).

- Ensure the baler has completed the compression and tying process.

⚠️ Safety tip: Always wear gloves and steel-toed shoes when handling metal bales.

2. Using a Forklift or Pallet Jack

- Recommended for medium to large bales.

- Steps:

- Position the forklift or pallet jack at the end of the baler where the bale is ejected.

- If the baler has a bale chute or roller table, let the bale slide onto it first.

- Lift the bale carefully using forks or a pallet, ensuring the load is balanced.

- Transport the bale to storage or shipping area.

- Position the forklift or pallet jack at the end of the baler where the bale is ejected.

💡 Many balers have a built-in roller conveyor that helps bales slide onto a pallet or forklift platform automatically.

3. Using a Grabber or Crane (Heavy/Industrial Bales)

- For very heavy bales (eg. large metal bales).

- Steps:

- Attach a bale grabber or hook to the crane.

- Engage the grabber securely around the bale.

- Lift the bale gently and move it to the storage area.

- Release the bale slowly, ensuring it lands safely.

- Attach a bale grabber or hook to the crane.

⚠️ Safety tip: Always check that the crane or grabber’s lifting capacity exceeds the bale weight.

General Tips

- Always wait until the compression ram has fully retracted before opening doors.

- Regularly maintain rollers or conveyor systems to ensure smooth bale movement.

- Keep hands and tools clear of the ejection path to avoid injury.

- For heavy bales, always use mechanical assistance (forklift, grabber, or conveyor).

- Check the baler’s manual for specific ejection controls and safety interlocks.

I agree that my personal data collected by SINOBALER is processed, used and stored in compliance with data protection exclusively for the purpose of processing my request.

PRIVACY POLICY

We collect information from you when you fill out an inquiry or contact form. When submitting the form on our site, you may be asked to enter your name and contact details such as: e-mail address, mailing address and/or phone number, etc. Alternatively, you can choose not to complete our forms and visit our site anonymously. Any of the information we collect from you may be used to help us to better respond to your individual needs, and/or enable us to more effectively respond to your customer service requests and support needs. The email address you provided may also be used to send you information and updates pertaining to your inquiry and/or order, in addition to receiving occasional company news, updates, related product or service information, etc. SINOBALER does not sell, trade, or otherwise transfer to outside parties your personally identifiable information. This does not include trusted third parties who assist us in operating our website, conducting our business, or servicing you, so long as those parties agree to keep this information confidential. We may also release your information when we believe release is appropriate to comply with the law, enforce our site policies, or protect ours or others rights, property, or safety.

By using our site, you consent to our online privacy policy. If we decide to change our privacy policy, we will post those changes on this page. If you have any questions or concerns regarding our privacy policy, please e-mail info@sinobaler.com or mail your question to us at 1206 Yinzhou Shanghui Nan Lou, 1299 Yinxian Avenue, Yinzhou District, Ningbo 315192, P.R. China.

EXTERNAL LINKS & DISCLAIMER

Our web site has links to many other organizations with their permission. Upon leaving the SINOBALER web site, you are subject to the privacy policy of the new site which are not under our control. SINOBALER is not responsible for the content of any linked site or any link contained in a linked site. These links are provided to you as a service for you to better understand the different business relationships that SINOBALER has established, and/or to point the reader to other possible relevant resources.